First of all, please see our one of our customer’s rubber tile making plant

If you want to know the detailed process of making rubber tiles, please watch below video.

This page only show Vulcanizing Press(Rubber Tile Making Machine) With Manual Female Mold Changing System, if you want to see Vulcanizing Press(Rubber Tile Making Machine) With Automatic Female Mold Changing System, please click Vulcanizing Press(Rubber Tile Making Machine) With Automatic Female Mold Changing System to see.

Application

After crushing used tires into rubber crumb, we need further process the recycled rubber crumb into useful goods, the simplest further processing is making recycled rubber crumb into colorful rubber tiles to pave gym, kindergarten, playground, etc. Our rubber tile making machine(vulcanizing press) is the right machines to make recycled rubber crumb into colorful rubber tiles.

Making high quality rubber tiles require to satisfy following conditions:

1). Constant temperature, our rubber tile making machine do this job well.

2). Constant pressure, our rubber tile making machine do this job well.

3). Exact curing time, our rubber tile making machine do this job well.

4). Raw Material mixed evenly according to formula, if you buy our rubber tile making machine, we will offer the formula free of charges.

5). Skillful workers and technical points, manage everything has a process from beginner to mature, your workers will inevitably encounter problems like this and that, if you buy our rubber tile making machines, our 20 years of professional experience will be your strong backing in making rubber tiles, if you buy our rubber tile making machine, we will offer whole life technical support and services.

Structure

Mainly consists of base, beams, pillars, heating plates, constant temperature controlling system, motor, pump, oil tank, oil cylinder, plunger, valves, constant pressure controlling system, timer, mold changing system, etc.

Principle and Work Process

Constant temperature controlling system will heat the heating plate and detect the heating plate temperature, after reach setting temperature, will stop heating, and after lower than setting temperature, will restart heating, so that the heating plates temperature keep constant.

Pushing the molds filled with material to the curing area, and push start button, the motor will start to drive pump make the oil flow from oil tank to oil cylinder to make the plunger go up to close molds, after reaching setting pressure, the motor will stop, generally speaking, the holding pressure valve will keep the pressure constant till reach setting time, but if the oil is not enough clean, impurities may affect the pressure holding affect caused the pressure decrease, if so, the motor will automatically restart to ensure the pressure constant.

After reaching the setting time under setting temperature and setting pressure, the tile will be cured enough, the holding pressure valve will open automatically to make oil flow from oil cylinder to oil tank, so that the mold open, after the mold open to the lowest position, workers can remove the finished tile from the molds, then start another curing cycle.

Due to taking finished rubber tiles from female mold and refill material to the female mold require time, in this term it is really a pity to make the rubber tile making machine wait, for ensuring the full capacity of making rubber tiles, we suggest equipping two female molds to each male mold, so that two female molds can work in turn, that is one is curing tiles, the other one discharging finished tile and refill material to prepare.

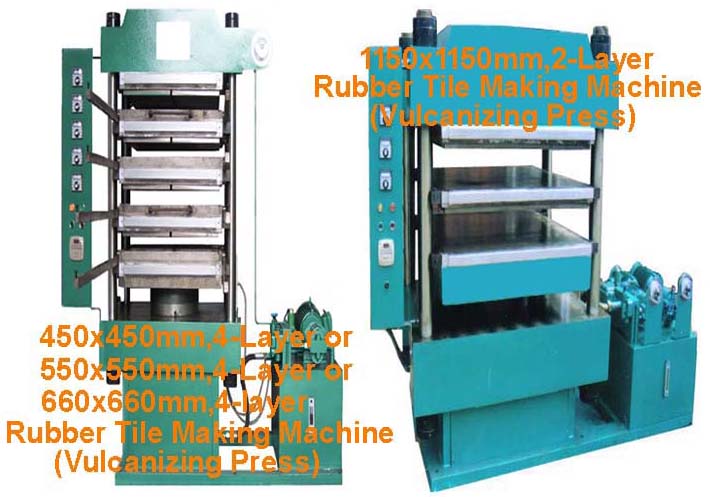

Specification and Price

Specification and Price

| Model: | 450x450mm,

4-layer |

550x550mm,

4-layer |

660x660mm,

4-layer |

1150x1150mm,

2-layer |

| Clamping Pressure: | 0.5MN(50Ton) | 0.5MN(50Ton) | 0.5MN(50Ton) | 1.6MN(160Ton) |

| Max Unit Pressure: | 24.69Kg/cm2 | 16.53Kg/cm2 | 11.48Kg/cm2 | 12.10Kg/cm2 |

| Pressure: | Maybe you will ask for making rubber tiles, 11.48kg/m2 pressure is enough or not, we can use our 20 years experience confirm to you that it is enough. If you want to bigger pressure, no problem, we can make according to your requirement. | |||

| Heating Plate Size: | 450x450x46mm | 550x550x46mm | 660x660x46mm | 1150x1150x50mm |

| Pillar: | 4 pcs, Ø75mm | 4 pcs, Ø75mm | 4 pcs, Ø75mm | 4 pcs, Ø105mm |

| Daylight Openning: | 175mm or customize according to your requirement. | |||

| Hydraulic Cylinder: | 1pcs | 1pcs | 1pcs | 1pcs |

| Plunger: | Ø200mm,1pcs, Ductile Cast Iron

(Better Than Cast Steel) |

Ø200mm,1pcs, Ductile Cast Iron

(Better Than Cast Steel) |

Ø200mm,1pcs, Ductile Cast Iron

(Better Than Cast Steel) |

Ø=360mm,1pcs,

Ductile Cast Iron (Better Than Cast Steel) |

| Plunger Stroke: | 450mm or customize according to your requirement. | |||

| Working Layer Quantity: | 4 Layer | 4 Layer | 4 Layer | 2 Layer |

| Oil Pressure: | 16Mpa | 16Mpa | 16Mpa | 16Mpa |

| Motor: | 1pcs 3Kw | 1pcs 3Kw | 1pcs 3Kw | 1pcs 5.5Kw |

| Heating method: | Electricity or Oil or Steam, we can make the heating method according to your requirement. | |||

| Control Method: | Automatically control constant curing temperature,

Automatic mold closing and opening, Automatic control constant curing pressure, Automatic control curing time, Manual control female mold changing. |

|||

| Temperature: | Max 200oC for Electricity type, Max 170oC For Oil Heating or Steam Heating Type | |||

| Dimension: | 2.2×1.71×1.95m | 2.3×1.81×1.96m | 2.4×1.90×1.96m | 4×2.55×2.05m |

| Weight: | 2600kgs | 2800kgs | 3000kgs | 6000kgs |

| Capacity Per time: | Max 0.64 sqm | Max 1 sqm | Max 1.44 sqm | Max 2 sqm |

| Capacity Per Hour Based on making 20mm thick rubber tiles: | Max 4.48 sqm | Max 7 sqm | Max 10.1 sqm | Max 14 sqm |

| The reason why take making 20mm thick rubber tiles as example: | Different thick tile need different curing time, the thicker tile you make, the longer curing time, the less capacity in square meter(Sqm), 20mm thick is the most popular thickness demanded by the market, accounting for about 80% tiles are 20mm, so we take it as an example, hope can help buyer make investment report much easier. | |||

| Production Lead Time: | 30Days | 30Days | 30Days | 30Days |

| Price: | Please contact us to inquire | Please contact us to inquire | Please contact us to inquire | Please contact us to inquire |

| Remarks: | Above Prices For Reference Only, For Final Price For You, Please Contact us. | |||

Photo Gallery

Following photo showing 1150x1150mm,2-layer Vulcanizing Press Manufacturing Workshop Corner, some heating plates, rubber tile mold plates and machine beams processed here.

Vulcanizing Press Manufacturing Workshop Corner

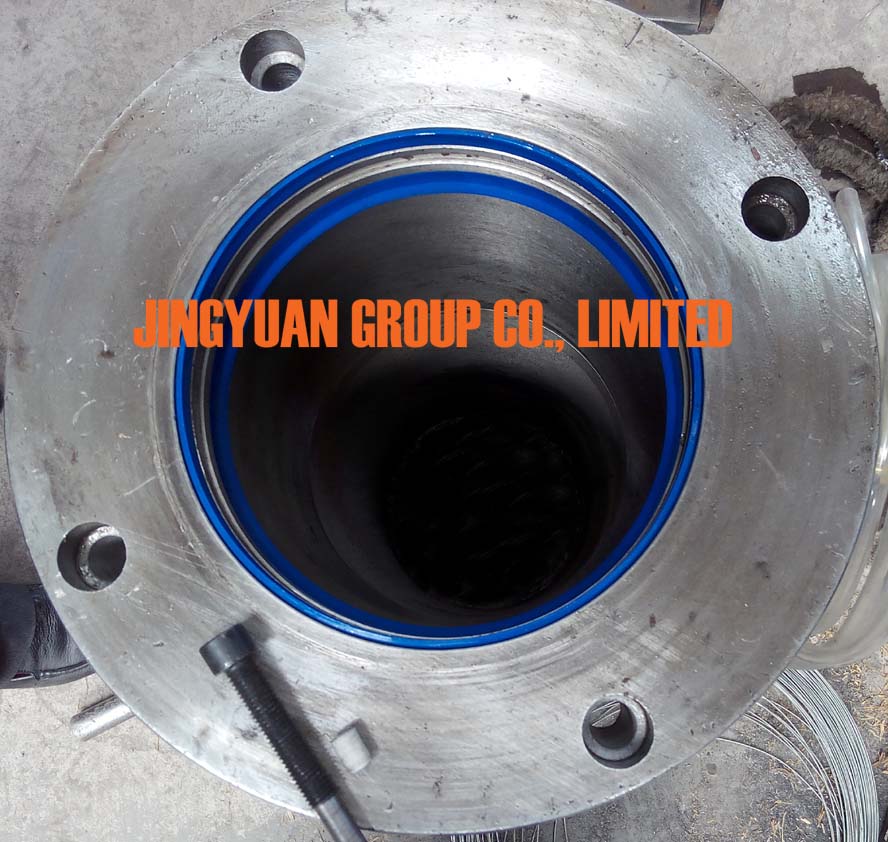

Following photo showing Vulcanizer Press Oil Cylinder installed with oil ring and anti dust ring, the oil cylinder is the main part of Vulcanizer Press, our works lathed inside, grind inside, clean inside carefully, so that they will not have any impurities to hart oil rings in future, and they must pass leakage test under constant 48 hours of 16Mpa pressure.

Vulcanizer Press Oil Cylinder

Following photo showing our Vulcaniser Machine plungers, the material is Ductile Cast Iron with fine grinding, the total cost is about 3 times more expensive than same size normal cast iron plunger in the market, 2 times more expensive than same size normal cast steel plunger in the market. The using life will be more than 30years.

Vulcaniser Machine plungers

Following photo showing a Vulcanising Machine Control Panel, used to control the machine to achieve constant temperature, constant pressure and exact curing time, once these data are set, no need change, every curing cycle only push start button on this panel, after reach curing time, the mold will open automatically.

Vulcanising Machine Control Panel

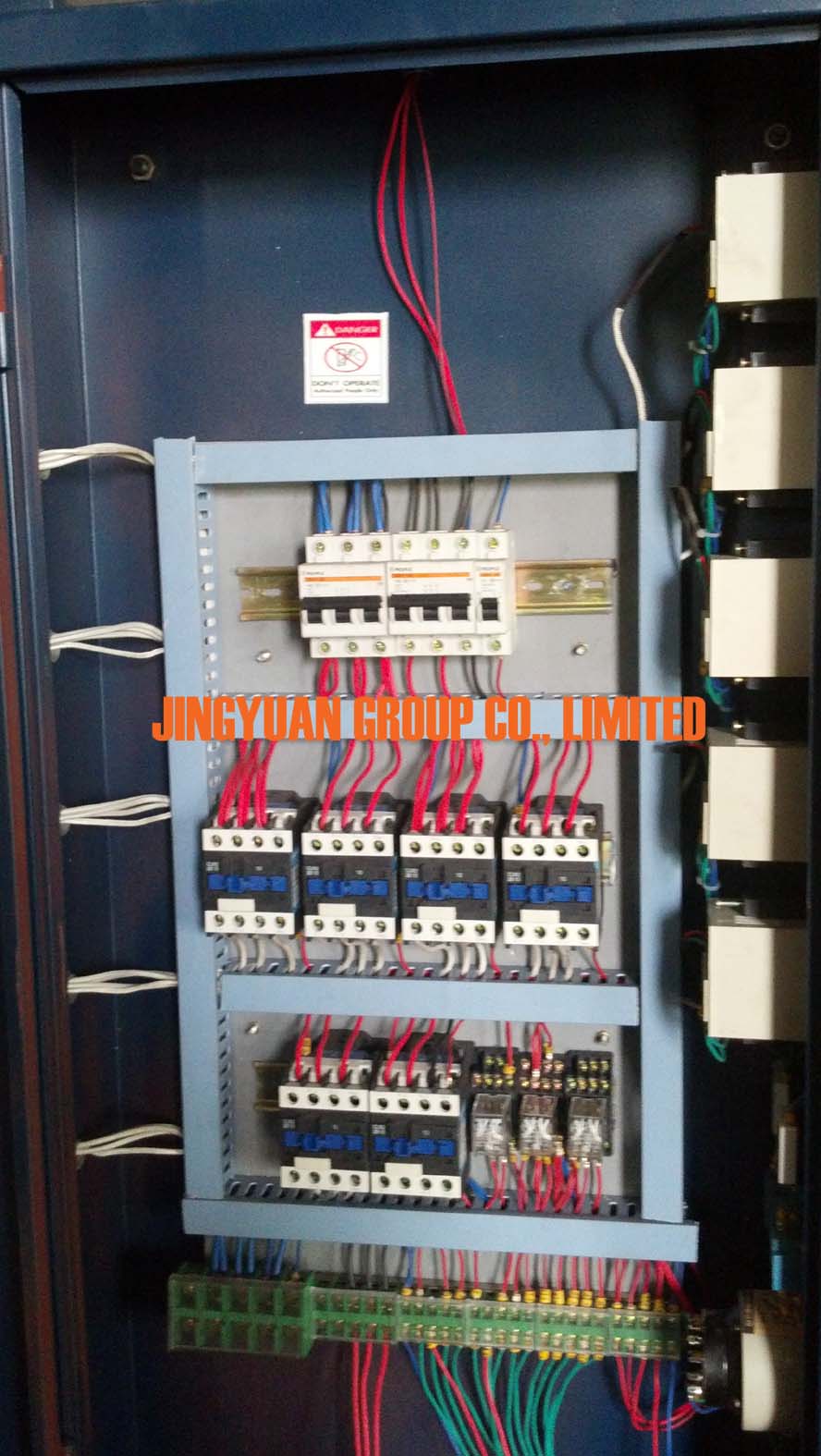

Following photo showing the Vulcanising Press Control Panel inside view, the elements include temperature controller, air switch, contactors, relays, timer, etc.

Vulcanising Press Control Panel Inside View

Following photo showing the Rubber Vulcanizing Machine Free Spare Part, which will be deliver to you together with our rubber tile making machine(vulcanizing press) to our customer, free of charges. These free spare parts include heating rods, oil rings, anti-dust rings, temperature conrollers,etc.

Rubber Vulcanizing Machine Free Spare Part

Normally speaking, the square rubber tiles has water ways at the back, the water way are made in making rubber tiles as following Vulcanization Machine work sketch showing. If you buy our rubber tile making machines, we will send you the drainage slotware which used to make water way, free of charges.

Vulcanization Machine working sketch

Following photo showing our 550x550mm,4-layer Vulcanizing Machines stocking area, you can see that 5 machines are in stock, ready for deliver to our customer.

Vulcanizing Machines

Following photo showing our 1150x1150mm,2-layer Vulcanizing Presses stocking area, you can see that 4 machines are in stock, ready for deliver to our customer. From it you also can see that the right machine has bigger openings and installed with thicker mold, because it is opening and molds are customized according to our customer’s requirement.

Vulcanizing Presses

Following photo showing a truck load 4 sets of 550x550mm,4-layer Vulcanizing Press For Sale , the truck is on the way from our factory to our customer.

Vulcanizing Press For Sale Before Road Transportation

Following photo showing a container loaded with two 1150x1150mm,2-layer Rubber Vulcanizing Press, but you may only can see the outer machine, because the other one is inside was blocked by the outer machine, the container is ready to deliver to our oversea customer by sea.

Rubber Vulcanizing Press

Following photo showing a container loaded with two 550x550mm,4-layer Vulcanizing Press Machine and some rubber tile molds inside, but you may only can see the outer two machine, because the other items inside was blocked by the outer machines.

Vulcanizing Press Machine

Following two photos showing some containers full of 4-layer Rubber Tile/Mat Machines(Rubber Tile Machine), often some big rubber tile/mat manufacturing factory bought rubber tile making machines(vulcanizing press) from us in bulk, these customers normally are our old customers, who already bought our machines before, so that they confirm our machine quality is very good, and they made a lot of money by our machines, so they buy our machines in bulk while expanding their rubber tile making business.

Rubber Mat Machine for sale

Vulcanizing Machine For Sale

Following photo showing we packed a Vulcanization Press by 15mm thick plywood case, this kind of package is suitable for less container loading shipment.

Vulcanization Press Plywood Package

Mayra Mowrym

Your vulcanizing presses has very nice looking and very good finishing, you will be my new vulcanizing machine supplier soon when I expand…

Bernardo Rose

If we buy your rubber tile making machines, can you give us the formula to make rubber tiles?

admin

Yes, if you buy our rubber tile making machine, we not only can offer you formula, but also can help you to buy the necessary raw material, or offer you the raw material manufacturers contact details, also give you the detailed production process, so that you can follow it to make rubber tiles successfully…

Sabby kohli

Please send me rice for 500*500 tile making machine and 1 mtr * 1 mtr. Tile press machine

admin

Hello, Sabby kohli, we just sent the catalog of our tile making machines(include price and details) to your Email, now you can find our reply in the inbox or spam box of your Email. Best regards, Web Admin

Ali Mahmoud

1- how to measure ( Max Unit Pressure ) ?

2- how much force per unit area needed to deform the rubber to tile ?

3- how to calculate force per unit area ?

4- can you make one for our company but pnumatic? (to make I shape interlock) 200x165x80

admin

hello,Ali Mahmoud,

Thank you for your questions.

1- how to measure ( Max Unit Pressure ) ?

—It is equal to max pressure divided by working area.

2- how much force per unit area needed to deform the rubber to tile ?

—-5-7kg/square centimeter will be ok.

3- how to calculate force per unit area ?

—It is equal to max pressure divided by working area.

4- can you make one for our company but penumatic? (to make I shape interlock) 200x165x80mm

—-Sorry, we only can make hydraulic press, we do not think penumatic is possible.

Best regards,

Web Master

Ronald

Do you ship to Africa? Zambia to be specific.

admin

Yes, we ship to Africa. Best regards, Admin

Saddam

I want to buy one, but there is a reason that makes me hesitant and afraid, which is the recipe of the mixture used. Not knowing how to make a batter is my problem.

Please send me a recipe for the mixture used, in order to know the availability of used items.

Jeevan Jadhav

Send detailed quotation for rubber tiles manufacturing.

Do not include Tyre powder processing unit.

admin

Hello,Jeevan, thank you for inquiry about rubber tile manufacturing. We just sent the details to your Email, now you can find them in the inbox or spam box, please. Best regards, Web Admin

Mohammad Abbas Arain

Send detailed quotation for rubber tiles manufacturing.

Do not include Tyre powder processing unit.