Application

Tire Block Crushing Line can make 5-40mesh(0.85-4mm) rubber powder and also can screen out some 40-120mesh(0.12-0.85mm) superfine rubber powder, if you want to want to get much more 40-120mesh(0.12-0.85mm) superfine rubber powder in future, you need rubber grinding machine to grind 5-40mesh(0.85-4mm) rubber crumb to 40-120mesh(0.12-0.85mm) superfine rubber powder, JYZM Series Rubber Grinding Machine is the right machine to do this job.

Structure

It consists of two parts, one part is JYZM-22 Superfine rubber powder grinder groups used to grind rubber crumb, the other part is JYLX-300 Centrifugal Screen used to screen out qualified superfine rubber powder, unqualified rubber crumb return to be grind again till be qualified, hereunder we instruct the both parts separately.

The JYZM-22 Superfine Rubber Powder Grinder Group normally consists of two sets or three sets of JYZM-22 Superfine Rubber Powder Grinders, blower, whirlwind collecting mechanism, water cooling mechanism, driving system, and electrical control system. Each Grinder consists of the frame, main motor for grinding, stepless variable speed motor for feeding material, speed reducing mechanism and a pair of grinding discs (a moving grinding disc and a static grinding disc).

The JYLX-300 centrifugal screen mainly consists of frame, motor, Input Openning, screening mechanism, two outlets, etc, as below sketch.

Principle

Through the relative motion of two grinding discs, shearing and grinding material to achieve getting superfine powder purpose, using water cooling to control the grinding temperature effectively, ensure the output superfine rubber powder quality, feeding mechanism adopts stepless variable speed, the feeding speed can be adjusted according to different materials, so that to get the most ideal products and quality, through whirlwind collecting mechanism collect the finished superfine powder, the whole process without any dust fly.

Process Description

Feed rubber crumb to the material hopper, the feeding screw will push the material forward and through the middle hole and the channel of the fixed grinder to the gap between the fixed grinding disc and rotation grinding disc, so that be grinded by two discs relative motion, the grinded material will be collected by whirlwind collecting machine and feed to the centrifugal screen, though the screen net rotation to form centrifugal force push qualified superfine rubber powder pass the screen holes and collected by another whirlwind collecting machine and feed to bag. The unqualified material will go out, so that to be feed to grinder to be grinded again.

Specification and Price

| Model: | 3-Grinder Type | 2-Grinder Type | 1-Grinder Type |

| Grinder Main Motor Power: | 22Kw x 3pcs | 22Kw x 2pcs | 22Kw x 1pcs |

| Feeding Variable Speed Motor Power: | 0.75Kw x 3pcs | 0.75Kw x 2pcs | 0.75Kw x 1pcs |

| Grinder Whirlwind Collecting Machine Motor Power: | 5.5Kw | 5.5Kw | 3Kw |

| Centrifugal Screen Motor Power: | 7.5Kw | 7.5Kw | 7.5Kw |

| Screen Whirlwind Collecting Machine Motor Power: | 3Kw | 3Kw | 3Kw |

| Total Power: | 84.25Kw | 61.5Kw | 36.25Kw |

| Dimension: | 7.5×3.5x4m | 6×3.5x4m | 4.5×3.5x4m |

| Weight: | 5500Kgs | 4000Kgs | 2500Kgs |

| Capacity: | 150-600kgs/hour | 100-400kgs/hour | 50-200kgs/hour |

| Grinding Disc Quantity | 1 Pair | 1 Pair | 1 Pair |

| Grinding Disc Diameter: | Ø260mm | Ø260mm | Ø260mm |

| Grinding Disc Speed: | 960rpm | 960rpm | 960rpm |

| Price: | Please contact us to inquire | Please contact us to inquire | Please contact us to inquire |

| Remarks: | Above price only for reference,please contact us for updated prices. | ||

| Production Lead Time: | 10-20days(Exclude Legal Holidays) | ||

Photo Gallery

Are you clear about the difference between 3-grinder type rubber grinding machine and 2-grinder type rubber grinding machine and 1-grind type rubber grinding machine? The following text and photos will be for helping you understand the difference.

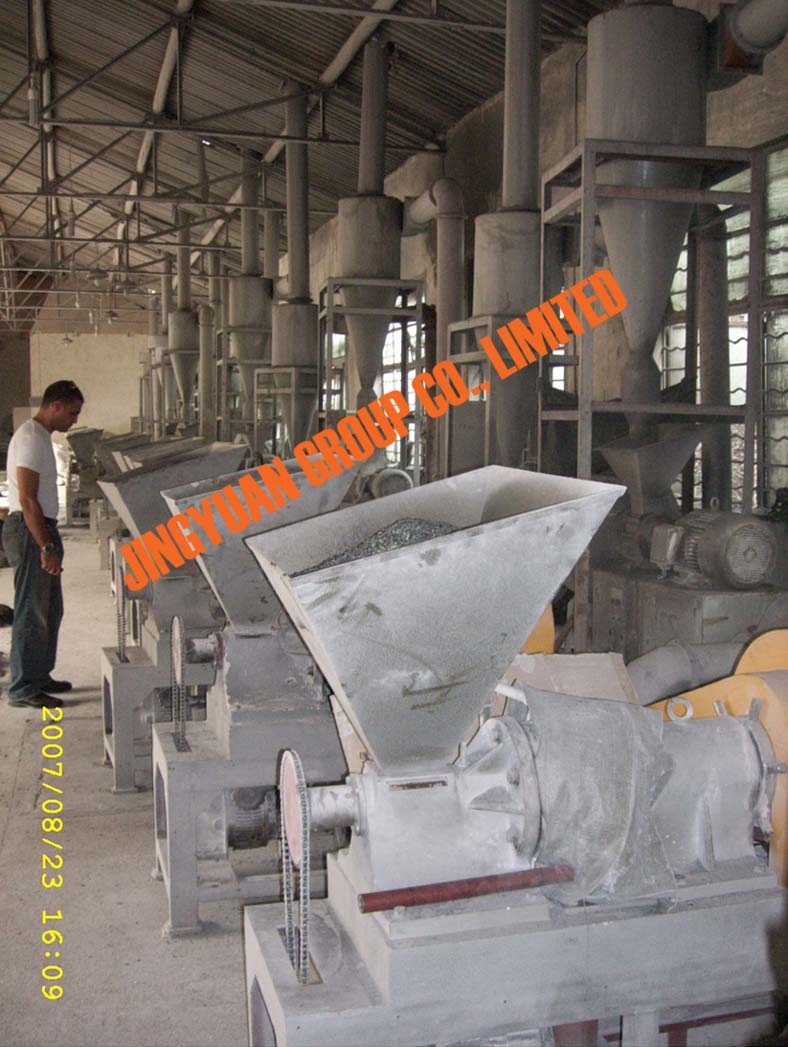

Following photo showing a 3-Grinder type superfine rubber powder grinding line(Rubber Grinding Machine), which include 3 JYZM-22 superfine rubber powder grinders(each power is 22.75Kw), one 5.5Kw whirlwind collecting machine, one centrifugal screen(7.5Kw) and one 3kw whirlwind collecting machine.

Rubber Grinding Machine

Following photo showing a 2-Grinder type superfine rubber powder grinding line(Rubber Grinding Machine), which include 3 JYZM-22 superfine rubber powder grinders(each power is 22.75Kw), one 5.5Kw whirlwind collecting machine, one centrifugal screen(7.5Kw) and one 3kw whirlwind collecting machine.

Rubber Grinding Machine(2-Grinder Type), you can add one grinder to this machine in future.

Following photo showing a 1-Grinder type superfine rubber powder grinding line(Rubber Grinding Machine), which include 3 JYZM-22 superfine rubber powder grinders(each power is 22.75Kw), one 5.5Kw whirlwind collecting machine, one centrifugal screen(7.5Kw) and one 3kw whirlwind collecting machine.

Rubber Grinding Machine(1-Grinder Type), you can add 1 or 2 grinders to this machine in future.

Seeing is believing, following photo showing a corner of the rubber grinding plant of our customer, who bought a lot of our 3-Grinder type superfine rubber powder grinding lines (rubber grinding machine) from us since 1996, in 2007, we take our foreign customer to visit this factory and take this photo, that means the rubber grinding machines in following photo had worked more than 10 years.

Rubber Grinding Plant is Grinding Rubber

Fasts Speak Louder Than Words, following photo showing a new rubber grinding plant, which installed two 3-grinder type superfine rubber powder grinding lines(rubber grinding machines) from us.

New Installed Rubber Grinding Machine

Simple is better than no, following photo showing an smallest rubber grinding plant, which installed one 1-grinder type superfine rubber powdering grinding line only.

Smallest Rubber Grinding Plant

Professional Cast high quality products, we are professional Rubber Grinding Machine Manufacturer, following photo showing the casting parts stock in open air, we cast these part ahead of time and lay them in open air for 12 months to eliminating of inside stress by natural aging, it is the best way to eliminate inside stress, this way can ensure the precise of the finished machine, and prolong the machine using life.

We are Professional Rubber Grinding Machine Manufacturers

Meticulous Attitude Make Perfect Machine, following photo showing our Rubber Grinding Disc workshop, the grinding disc manufacturing process include cutting, milling, welding, drilling and grinding, etc.

Rubber Grinding Disc Manufacturing Workshop

Don’t let cheap to be your motives, following photo showing finished rubber grinding disc(rubber grinder mill), which are the main part of grinding rubber crumb to superfine rubber powder, the disc with a middle hole is the fixed disc, the other one is rotation disc, the crumb rubber will be feed by a screw feeder through the fixed disc middle hole and divergent groove to be grinded by two grinding discs relative motions, both fixed and rotation disc inlaid a lot of Tungsten Alloy, the alloy cost price is about US$100/kg.

Rubber Grinding Disc Front View

Experience is the best teacher and designer, following photo showing backing of both fixed disc and rotation disc, the small holes are for screw bolt use, the middle holes are for water cooling use, the big hole is for material feeding.

rubber grinding disc back view

Safety is the first, following Photo Showing Electrical Control Panel Front View for one 3-Grinder type rubber grinding machine, it control the rubber grinding machines work effectively, safety and smoothly, it include one voltmeter, 3 ammeters, start buttons and stop buttons for 3 grinders, 3 feeding screws, 1 whirlwind collecting machine(another whirlwind collecting machine’s and 1 cooling water pump.

Rubber Grinding Machine Control Panel

Following photo showing the inside of the electrical control panel, from it you can see that our electrical control panel wiring is very neat, and each cable with marked numbers on both end, very convenient for users to use and check them following electrical circuit diagram.

Rubber Grinding Machine Control Panel Inside View

User experience is more important than machine cost, following photo showing our centrifugal screen of our rubber grinding machine, it has transparent glass fiber reinforced plastic window, ensuring the rubber screening process is closed and visible.

Rubber Grinding Machine’s Centrifugal Screen

Some customers bought other company’s rubber grinding machines, but can not make benefit at all, then turn to us bought little rubber grinding machines at the beginning, then they found our machines quality is very good and can make a lot of money for them, so that they buy our rubber grinding machines in bulk after confirming the quality of our machines is indeed high. Following Photo showing a 40ft container full of rubber grinding machines before shipping to our customers.

Rubber Grinder was loaded in one 40ft container before ship to our oversea customer.

Facts speak louder than words, different customer want different machine color, we will paint the machine color according to buyer’s color chip. And Due to the machines is relatively large, we will dismantle them and load into container like following photo, the buyer can install them easily following the instruction manual.

Rubber Grinding Machines was loaded in one 40ft container before ship to our oversea customer.

We will provide good after-sale service and high quality spare parts at cost prices, following photo showing we packed a lot of rubber grinding machine discs in a steel case before ship to our customer, due to have a lot of rubber grinding machines and business is booming, use out a lot of grinding discs, so that they also buy spare rubber grinding machine discs from us in bulk.

Rubber Grinding Discs Packed in a steel box before ship to our oversea customer.

Video Gallery

Do you want to see how to grind rubber? If so please click below video and watch on line.

If you have any question or comment about our rubber grinding machine(superfine rubber powder grinding line) please feel free to contact us or leave your comment below. Every point of your idea will be valued by us.

Luis Jennings

This Rubber Powder Grinding Line is very nice, we have used it to grind rubber powder and talcum powder for many years. Each year change grinding disc two times.

Dennis Moss

I saw the price for the 200-300 Kg/hr. plant with fiber separator is $29,800.00. Does that include shipping and diagram for installation?

I will be part of a new business in my community and need to start small and grow. Suggestions were to market crumb product and powder would be helpful.

Shipping would be to Negros Island, Philippines

Best regards Dennis Moss

admin

Hello,Dennis Moss, thank you for inquiry, I just send our reply to your Email, please find our reply in your Email, Best regards, Admin

Mostafa

Hi Dear,

I want to buy a rubber powder making. can you send me the catalog and technical information of your products?

admin

Hello, Mostafa, thank you for comments, we just sent rubber powder making plant detail to your Email, now you can find the file in the inbox or spam box of your Email. Best regards, Web Master.

Filip

We are interested in your equipment.

admin

Hello, Filip, Thank you for inquiry, we sent you an Email about our tire recycling plant. Please find our answer in your Email inbox or spam box. Best regards, Admin

Sarbjit Singh

We are looking for an used tyre grinding plant.

Our required production is 300 kg per hr.

admin

Hello, Sarbjit Singh, Thank you for inquiry, we just sent you an Email with a file, please find the file in your Email inbox and spam box. If you have any question, please contact us by replying our Email, Ok? Best regards, Admin

rama

can i get the pricing for each machine and the use of it?

admin

Hello, Rama, Thank you for inquiry, we just sent our machine catalog with price to your Email, please find the file in your Email inbox or spam box. Best regards, Admin

ANDRES PLASCENCIA SASHIDA

Hi I´m interested in your equipment

admin

Hello,ANDRES PLASCENCIA SASHIDA, thank you for inquiry, we just send catalog of our tire recycling machines with prices to your Email,please find the file in your Email inbox or spam box. Best regards, Admin

Samuel Smoch

hello,

can i get the pricing for each machine and the use of it?

admin

Hello,Samuel Smoch,Thank you for inquiry, we have send the pricing for each machine and the use of it to your Email, please find the files in your Email inbox or spam box. Best regards, Admin

Richard Elgin

I am looking to start a new tire grinding operation. Would like to start out small to see the benefits and profitability. Thanks, Richard

admin

Hello, Richard, Thank you for inquiry about JYZM series rubber grinding machine, we just send the price and details to your Email.

By the way, this machine can not grind tire directly, it only can grind the recycled rubber crumb. Regarding how to make recycled rubber crumb, we just sent different capacity tire recycling plant, from this file, you can see different capacity tire recycling lines, and from each one, you can see the process sketch, machine list, prices, working area, worker needed, and average power consumption, etc. Now you can find the files in the inbox or spam box of your Email, please. Best regards, Web Master

Thapa

Hello sir

Can you send me catalogs of your different machine please.

Greetings

admin

Hello, Thapa, thank you for inquiry, we just sent the catalog of different machines to your Email, now you can find the files in the inbox or spam box of your Email, please. Best regards, Web Admin

Thatayaone B Sebidie

Kindly share a full production line catalogue and quotations

Thank you

admin

Hello,Thatayaone B Sebidie, thank you for inquiry, we have sent full production line catalog and quotations to your Email, now you can find the file in the inbox or spam box of your Email, please.Best regards, Web Master

orlando braga

WE WOULD LIKE TO RECEIVE A PRICE COTATION FOR A GRINDING TIRE MACHINE.

WE NEED PARTICLE BETWEEN 0-300 microns

admin

Hello, orlando braga, thank you for inquiry about our tire recycling plant to make 3-300microns rubber powder, we just sent price and details of different capacity plants which can satisfy your requirements to your email, now you can find the file in the inbox or spam box of your Email. Best regards, Web Master

Ozgur Guney

Hi,

we would like to turn our vulcanized silicone rubber scraps into dust which machine would you recommend? Thanks

admin

Hello,Mr.Ozgur Guney,

Thank you for inquiry.

What is the size of your vulcanized silicone rubber scrap?

what size dust do you want to get?

Could you please send me some photos of your silicon rubber scrap, so that we can recommend you right machines?

Best regards,

Web Master