All Rubber Floor Molding Molds on this page can be installed on 2300x1150mm Vulcanizing Press(Rubber floor molding Machine) to make high quality rubber floor tiles.

The input material is Rubber Crumb, PU binder and Iron Oxide pigment after mixed by Rubber Crumb Mixers.

The output is High Quality Rubber Floors, the finished floor tile shape and size is the same as its mold.

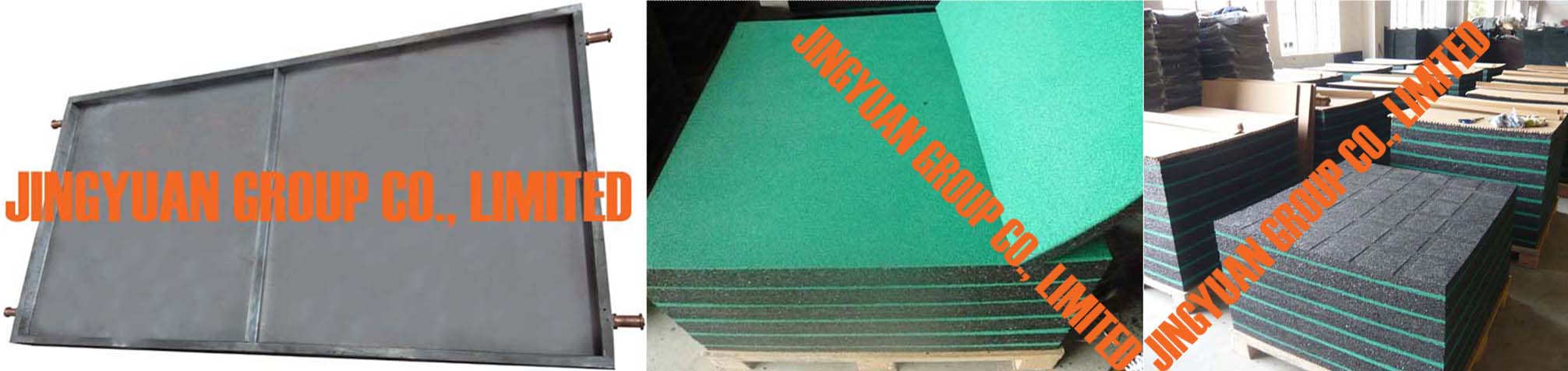

2000x1000mm Rubber Floor Moulding Mould

| (2-5-01). | 2000X1000mm Rubber Floor Tile Molding Molds(1 Cavities Per Female Mold) | ||

| Price: | Please contact us to inquire | For 1 Male Mold And 1 Female Mold | |

| Please contact us to inquire | For 1 Male Mold And 2 Female Molds | ||

| Please contact us to inquire | For 2 Male Molds And 4 Female Molds | ||

| Production Lead Time | 20-30Days(Exclude Legal Holiday) | ||

| Tile thickness | Adjustable | ||

| (2-5-02). | 1000X1000mm Rubber Floor Tile Molding Molds(2 Cavities Per Female Mold) | ||

| Price: | Please contact us to inquire | For 1 Male Mold And 1 Female Mold | |

| Please contact us to inquire | For 1 Male Mold And 2 Female Molds | ||

| Please contact us to inquire | For 2 Male Molds And 4 Female Molds | ||

| Production Lead Time | 20-30Days(Exclude Legal Holiday) | ||

| Tile thickness | Adjustable | ||

500x500mm Rubber Floor Moulding Mould(8-Cavity)

| (2-5-03). | 500X500mm Rubber Floor Tile Molding Molds(8 Cavities Per Female Mold) | ||

| Price: | Please contact us to inquire | For 1 Male Mold And 1 Female Mold | |

| Please contact us to inquire | For 1 Male Mold And 2 Female Molds | ||

| Please contact us to inquire | For 2 Male Molds And 4 Female Molds | ||

| Production Lead Time | 20-30Days(Exclude Legal Holiday) | ||

| Tile thickness | Adjustable | ||

Photo Showing How To Mold Rubber(Install Rubber Floor Moulding Mould on Vulcanizing Machine)

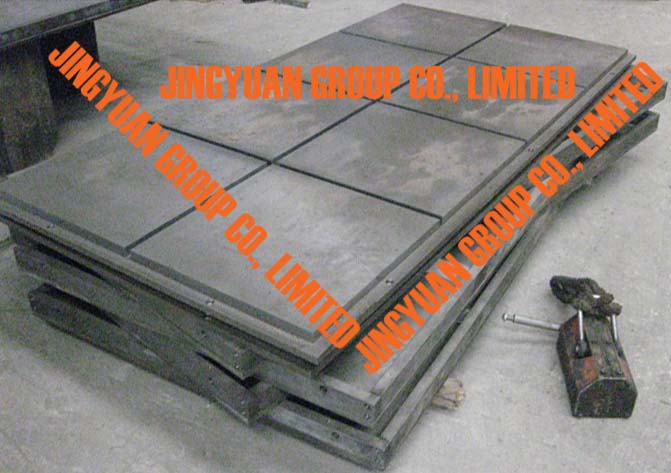

Minimum Ordered Quantity:1 male mold and 1 female mold of any mold you like.

For ensure maximum production speed by one 2300x1150mm, 2-layer Vulcanizing Press, we suggest you buy at least 4 male molds and 8 female molds, so that 4 working layers can make Rubber Floor Tile at the same time and 8 female molds work in turn, that is when 4 male molds and 4 female molds is making Rubber Floor Tiles, the other 4 female molds can discharge finished tile and refill new material to prepare, avoid the finished tile discharging and new material refilling take curing time.

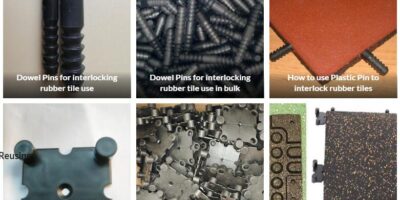

You can decide whether to make drainage channel(water way) on Rubber Floor Tile back.

Following photo showing the sketch of how to make waterway at the Rubber Floor Tile back, the drainage slotware will be delivered to you together with the Rubber Floor Tiles molds.

How to Make Rubber Tiles Waterway by Rubber Floor Molding Molds

Following photo showing the waterway slotwares we will put in one female mold and send to you free of charge.

Rubber Floor Molding Molds Waterway Slotwares Packing

From above photo, you can see that each female mold has two layers, so that you can remove one layer to adjust the finished tile greatly (from example from 40mm to 20mm), for ensuring you can change the finished tile thickness small (for example from 20mm to 25mm, from 25mm to 30mm,etc), we will send you enough Rubber Floor Molding Mold spacers as following photo showing.

Rubber Floor Molding Molds Spacers

You can decide whether to coat Teflon or not,following photo showing a rubber floor molding mold coated with Teflon coating, which can avoid the finished rubber floor tile adhere to the mold.

Rubber Floor Moulding Mould With Teflon Coating

Above prices did not include the Teflon coating cost. Following photo showing a Rubber Floor Molding Mold coated with Teflon coatings, which can avoid the finished adhere to the Rubber Floor Molding Mold. You can decide whether to coat the mold with Teflon coating or not, if you want to know Teflon coating cost, please feel free to contact us.

Do you want to watch the video of making rubber floor tiles by vulcanizing machine and rubber floor molding molds? If so, please click below video and watch online.

Maynard Covey

I like this rubber tile floor mold, it can make so many floor tiles at same time,my purchasing staff will contact you to buy this mold soon, congratulations!

Ashraf

So many rubber tile openings on eacg female mold, the rubber tile making capacity must be very high