Application

Only rubber granules certainly can not make out rubber tiles, for forming rubber granules into rubber tiles, you need to mix with PU Binder, for making different color rubber tiles, you need to mix with different color Pigment, the Rubber Crumb Mixer will do the job of mixing rubber granules, PU binder and Pigment evenly.

Structure

Mainly consists of machine frame, motor, speed reducing mechanism, main shaft, stirring device, barrel, V-belt, handle, etc.

Principle

Motor drive the stirring device rotate to push the material go up and down frequently, so that the rubber granule, PU binder and Pigment fully mixed evenly.

Specification and Price of Rubber Crumb Mixers

| Model: | 4-Berrel Mixer | 250L Mixer |

| Motor Power: | 2.2Kw | 4Kw |

| Dimension: | 1.52 x 0.76 x 2.06m | 1.15M x 1.15M x 1.15M |

| Weight: | 160kgs | 180kgs. |

| Input: | Rubber Granule, PU Binder and Pigment(Due to rubber tile top color layer demand material less material and often need to change color, we designed this mixer accordingly, it has 4 small changable barrels, so that you can use different barrel to mix different color rubber tile top layer material, for avoiding to clean the barrel frequently). | Rubber Granule, PU Binder(Due to rubber tile bottom layer demand more material and no need to change color,we designed this mixer accordly, it has 1 big fixed barrel only, so that can mix big amount material. We do not suggest to use this machine to mix rubber tile top layer color material, because cleaning barrel will waste too much time). |

| Output: | Evenly Mixed Rubber Granule, PU Binder and Pigment | Evenly Mixed Rubber Granule and PU Binder |

| Barrel Capacity | 100L | 250L |

| Mixing Speed: | 220rpm | 30rpm |

| Price: | Please contact us to inquire | Please contact us to inquire |

| Delivery Time: | 10days(Exclude Legal Holiday). | |

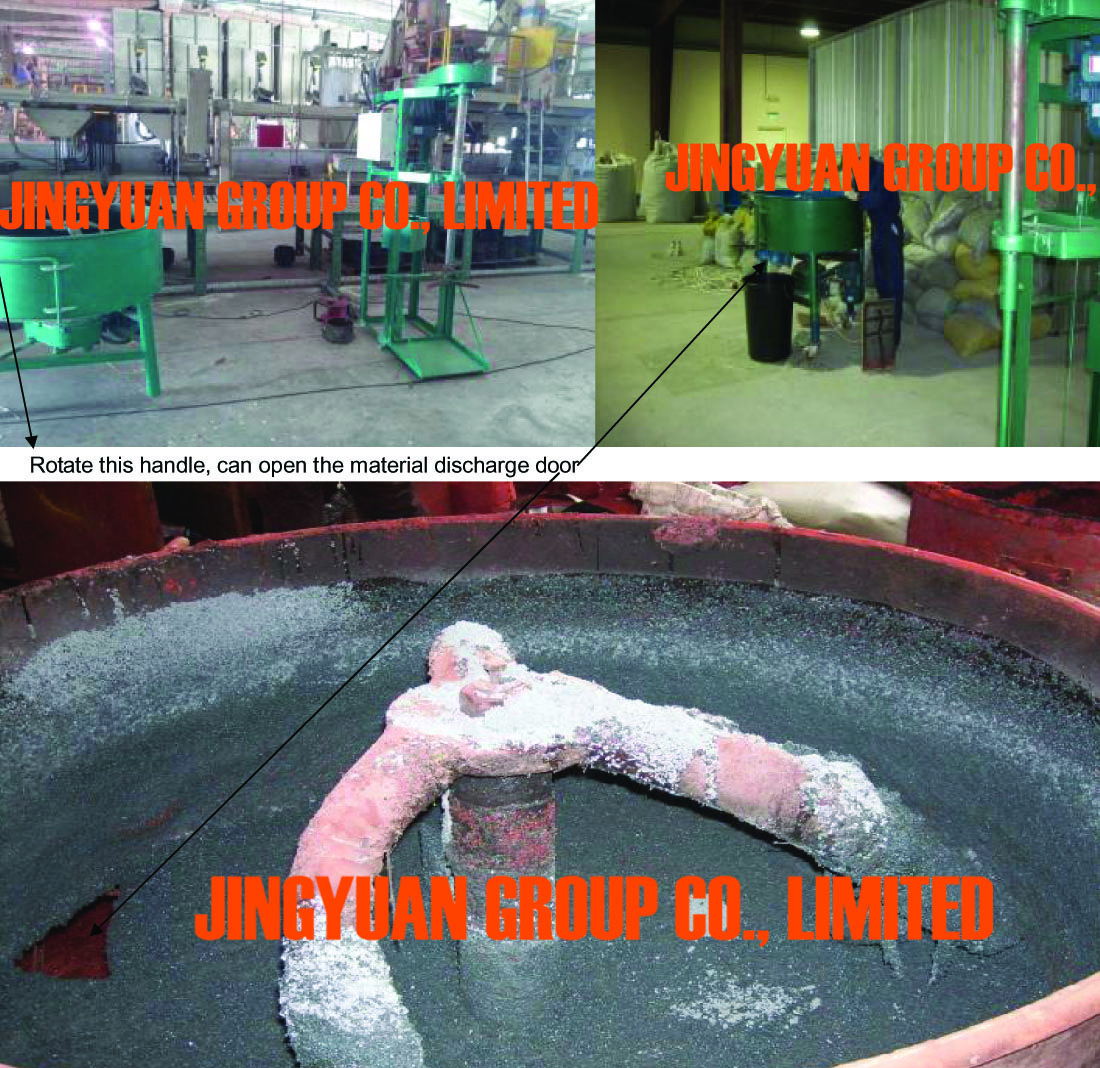

Maybe you will ask how to feed material and discharge material from these rubber crumb mixers. For the 4-barrel mixer, due to the barrel is removable and is very light, it feed and discharge material from top.For the 250L mixer, due to the barrel is fixed and big, it feed material from top, discharge material from bottom, there are a door at the bottom, you can open the door by rotating the door handle as following photo showing.

Maybe you will say these mixers represent backward productivity by manual operation, but following photo showing that they are installed before automatic rubber tile making machines to do some jobs that automatic rubber tile making machines can not do.

Rubber Crumb Mixer used for automatic rubber tile making machines, this photo was taken in our customer factory workshop.

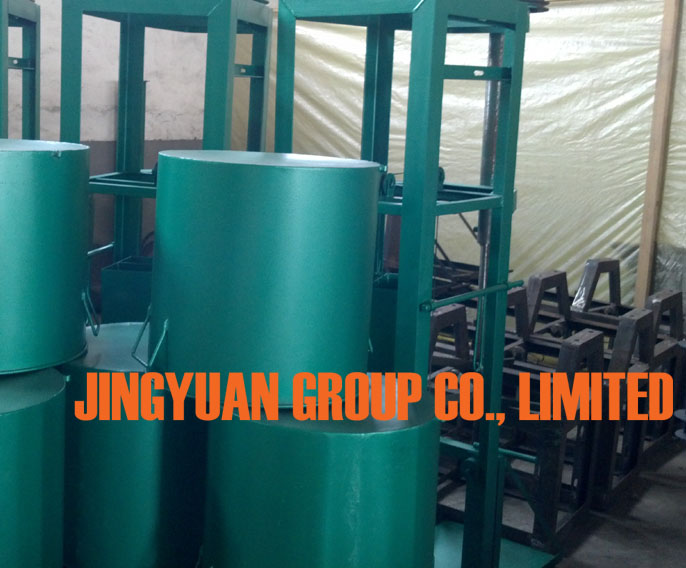

Craftsman spirit cast high quality machinery. Following photo showing our workers is concentrating on producing the 4-barrel rubber crumb mixers.

Rubber Crumb Mixer Manufacturer is welding the barrel holder of 4-barrel mixer.

Following photo showing half-finished 250L rubber crumb mixer, they will be painted with anti rust paint and outside paint according to our customer requirement.

Half finished 250L Rubber Crumb Wet Pour Mixers in stock, waiting to be painted with anti rust paint and outside paint.

Following photo showing some painted 4-barrel rubber crumb mixers and some unpainted 4-barrel rubber crumb mixers stock together, the painted has been sold out, ready for shipment, the unpainted will be painted with anti rust paint and the outside paint according to buyer’s color chip.

Painted and half finished 4-Barrel Rubber Crumb Mixers in Stock

Following photo showing a big rubber tile manufacturing factory bought 7 sets of 250L rubber crumb mixers from us, the light green color are painted according to his requirement.

250L Rubber Crumb Mixer painted according to our customer’s color chip.

Following photo showing we loaded some rubber tiles molds and one 4-barrel rubber crumb mixer and one 250L mixer on a truck, it is ready to deliver to our customer by road transportation.

Rubber Crumb Mixer For Sale loaded on a truck before road transportation

Following photo showing the ways we load 250L rubber crumb mixers in container, we put two 250L rubber crumb mixers in stack for saving the space to contain more other items in same container, for avoiding the mixer shake, we use steel wires fastened the mixers to the container inside hooks.

Rubber Crumb Mixer loaded and fastened in container before deliver to our oversea customer by sea.

Following photo showing we load one 4-barrel mixer and one 250L mixer on top of rubber tile molds package for saving space to contain other items in same container, the mixers body are fasten by steel wires to the container hooks.

Rubber Crumb Mixer loaded on top of various Rubber Tile Molds in container.

If want to see how it mix rubber granule, PU binder and Pigment, please click below video and watch online.

![]() Attention Please: When making this video,

Attention Please: When making this video,  works well in China, but now it does not work in China, so that you can not contact us by

works well in China, but now it does not work in China, so that you can not contact us by  , if you want co contact us, please click here to contact us by other ways.

, if you want co contact us, please click here to contact us by other ways.

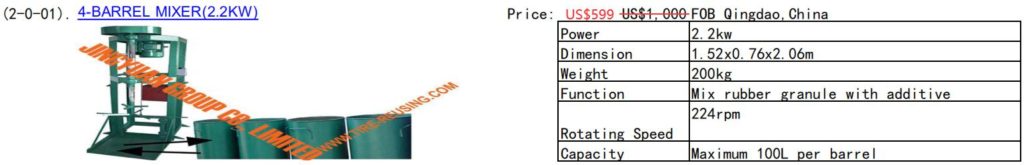

By the way, the 4-barrel mixer and 250L mixers are on special promotion as below:

For 4 barrel mixer, the original price is US$1000, the promotion price is US$599.

Natalie

Hello, please send me quotation for rubber crumb mixer with delivery term.

Best regards nataly

admin

Hello, Natalie, Thank you for inquiry about mixer for crumb rubber. We have many types of Crumb Rubber Mixers, for specification and price of each one, please visit http://www.usedtirerecycling.com/?s=mixer, could you please me know which one do you prefer, so that we can quote you the relative price and delivery time of it? Best regards,Admin

Abhi

Hello, please send me quotation for rubber crumb mixer.

admin

Hello,Sir, thank you for inquiry, we just sent the quotation to your email, now you can find the quotation in the inbox or spam box of your Email, please. Best regards, Web Admin

Andres

Dear JINGYUAN GROUP CO., LIMITED Team,

I hope this message finds you well.

I am currently working with one of your mixer models, and I need assistance with opening the speed reducer for maintenance purposes. Could you please provide detailed instructions or a manual on how to properly disassemble the speed reducer of this specific mixer?

Your guidance on this matter would be greatly appreciated.

Thank you for your support.

Best regards,

admin

Dear Andres, hope this message finds you well, too. We just send you an Email, could you please take a photo of the mixer’s nameplate and send us by replying our Email, so that we can guide you with the maintenance exactly? Best regards, Web Admin